Vortex® MAX is a patented engine precleaner that combines proven, powered technology with high-efficiency filtration, protecting engines from the harmful impact of dust and debris. The small footprint, high-airflow system (higher than single XLR Powered Precleaner) provides constant and sustained precleaned air downstream to the engine, improving machine performance, reducing costly downtime, and lowering total cost of ownership.

How it Works: The Sy-Klone Effect

The separation and ejection of debris, and high-efficiency filtering, all of which precleans air, is The Sy-Klone Effect.

- Dirty air enters the precleaner housing through the inlet end.

- The debris-laden air is directed into a rotation – a “Vortex” – pushing the debris to the outside walls through centrifugal force. The debris rotates towards the outlet end.

- Debris is ejected through the ejection port, and the fine dust that remains passes through Sy-Klone’s self-cleaning filter.

- After passing through the high-efficiency filter, clean air is passed downstream to the engine and engine air filter through the outlet end.

Benefits and Features

Maximize Clean Air Downstream to the Engine

- Proprietary powered precleaning technology, combined with high-efficiency filtration

High-Airflow System

- A single system provides protective power of clean air for a wide range of high-airflow machines

Reduce Total Cost of Ownership, Improve Productivity

- Provide sustained, clean air flow regardless of the machine’s operating state, even in idle

- Minimize downtime and maintenance costs

- Reduce dirty air downstream, which can abrade engine components and damage exhaust and aftertreatment systems

- Extend life of primary engine filter and engine, meet maintenance intervals

Versatile Installation Options

- Available in 12V and 24V configurations

- Compact size and footprint with variable mounting configurations

- Less expensive and easier installation as compared to multiple unit smaller airflow systems

XLR Powered Precleaner for Engines

Sy-Klone® International now offers the XLR Powered Precleaner® for maximum precleaning in impossible environments with the lowest possible restriction to protect your engine! This high efficiency powered precleaner removes 99.99% of ISO fine test dust. With the addition of power, there is zero restriction up to 130 CFM (3.68 m3/min).

- High efficiency powered precleaner removes more than 90+% of the dust BEFORE it reaches the prefilter.

- High efficiency radial seal prefilter then removes 99.99% of ISO fine test dust.

- Patented self-cleaning prefilter drops dirt continuously, which is then ejected from the XLR filter housing.

The XLR Powered Precleaner offers two sizes to maximize your precleaning ability. The unique design allows for an easy air filter change with no engine contamination.

Benefits:

- Most effective “impossible dust environment” engine precleaner ever invented

- Lowers cost per operating hour

- Quickly recover cost of investment

- Extends primary engine air filter life for an indefinite period of time

- XLR prefilter changes do not expose engine to field service contamination

- Improved oil samples (significantly lower contaminate levels)

- Helps to preserve your engine, catalytic converter, and prevents related downtime costs

How XLR Works:

XLR = eXtra Low Restriction

- Debris-laden air enters the precleaner.

- The motor whips the air into a vortex with the debris riding along the outer walls.

- Debris is ejected from the precleaner.

- The clean air in the center of the system is then pushed through the filter with very low restriction.

- The filter and housing are self-cleaning as debris falls off the filter and is then ejected from the housing.

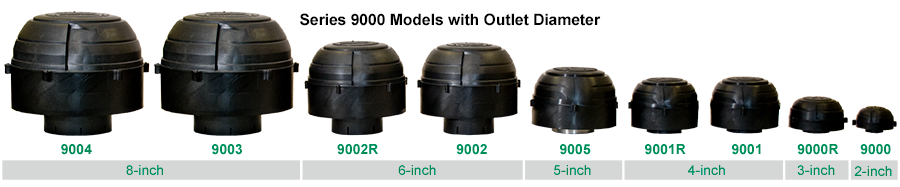

Series 9000 Precleaner

Air filter life is directly related to the amount of debris ingested through an engine’s air intake. Installing a Sy‑Klone Series 9000® Air Precleaner as the first stage of an air intake system prevents the majority of heavier-than-air particles from entering the system. This results in longer air filter life, more efficient engine performance and decreased maintenance expenses.

Always select model based on engine airflow requirement, then use adaptation for any difference in diameter.

Series 9000 Benefits:

- Extends air filter life, which increases uptime

- Handles all kinds of mixed debris, including mud, snow, rain, leaves, sawdust, chaff, and dust

- Lowers cost per operating hour by reducing parts, labor, and downtime costs

- Lowers air restriction, which increases useable horsepower and improves fuel efficiency

- Easy to install – we have adaptation kits and parts to fit almost any machine

- Claims against our limited warranty are practically nonexistent

- Rugged engineered polymer construction gives you the strength of steel (without the corrosion) at the cost of plastic; the opaque material prevents operator being distracted by visible moving parts

How it Works:

- Air enters the underside of the dome through screened louvers, which prevents clogging by blocking any particles larger than the ejection slot from entering the unit.

- Curved particle accelerator blades slam air and dirt up against the sidewall

- Strakes along the interior surface move heavier-than-air debris towards the ejection slot

- Clean air continues to swirl down into the engine air inlet pipe